Back to top

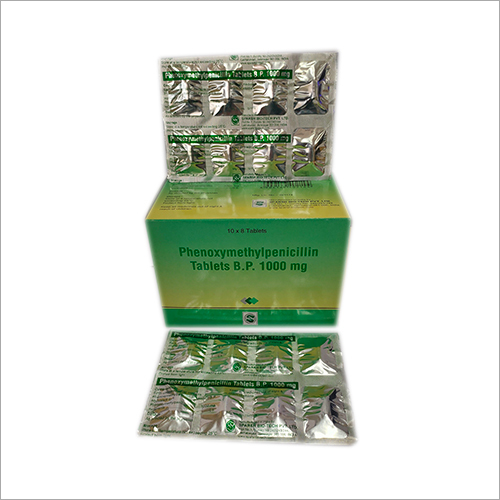

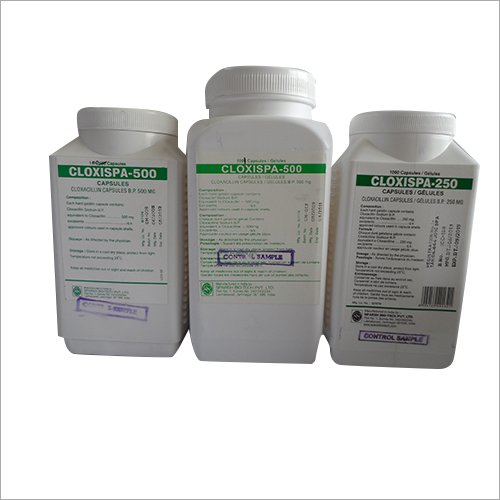

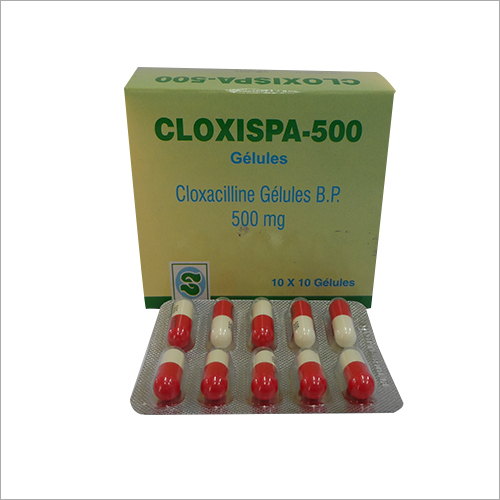

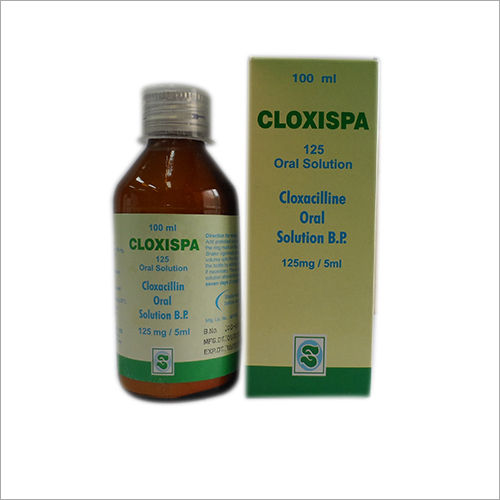

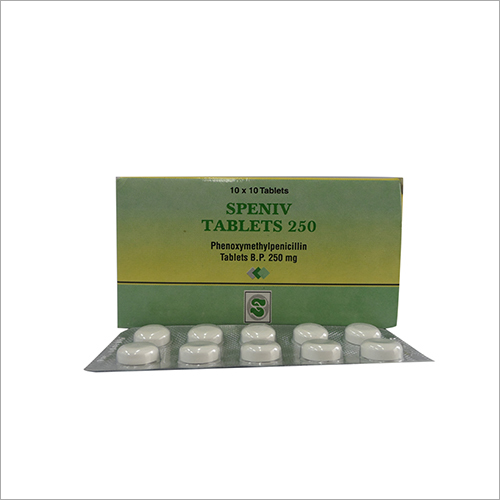

Manufacturer of Cefalexin Capsules and Syrup, Phenoxymethylpenicillin Tablets, etc.

About Us

Sparsh Bio-Tech Pvt. Ltd. is registered under Company Act 2000, and works with the mission to offer the best products. We are counted among the top manufacturers, exporters and suppliers of Cloxispa Capsules, Co-Fluampicil Oral Syrup, Spamclox Syrup, Cefalexin Oral Syrup, etc. We not only conduct research work before carrying out the production process of our products but check the end products as well before their dispatch. Our company is proud to be a part of an industry that is serving mankind and promoting good health. We will keep on launching new products that will be more effective and can cure aliments just in few doses.

The support of our directors has enabled the company to grow and earn a reputed image in the market. The following are some names under whose guidance we have secured tremendous success in the industry:

Mr. P. N. Maru (Managing Director): He is a visionary person with an impressive sense of business and rich experience of over three decades.

Dr. A. J. Maru (Director): He holds a vast experience of around 26 years as a General Practitioner for Human Medicine. He is a successful businessman of Pharmaceutical Exports for 8 years and has a great way of handling operations.

Mr. R. H. Haria : He is an NRI director and was based in East African Countries for more than 20 years. He is the main handler for our Marketing and Sales operations in African Sector.

Mr. P. J. Maru & Mr. S. P. Maru: Both of them have rich experience in finance, sales and administration. They are the strongest assets to our company.

Our Presence

We are serving worldwide customers from various countries including India, Vietnam, Sri Lanka, Uganda, Congo, Kenya, Cambodia, Zambia, Rwanda, etc.

Quality Policy and Management System

We are committed to delivering the best quality of products like Cefalexin Oral Syrup, Spamclox Syrup, Co-Fluampicil Oral Syrup, Cloxispa Capsules, etc., that are effective. Our professionals follow all the quality norms while carrying out the different stages of the production process. The employees are trained in a particular function, which complies with cGMP before letting them handle floor operations.

We have hired quality inspectors who carry out inspection and make sure that all S.O.P. and B.M.R guidelines are being followed. These professionals also check the quality of the raw material, and without their approval no input is used by the production professionals. Also, the end product is not allowed to be delivered without the assurance of quality from our quality management team.

Our Plant

Our production plant is integrated with B-Lactum facilities, which help us produce Penicillin Anti-Biotic. The B-lactum facility that we own is certified by WHO-GMP (Food & Drug Control Administration of Gujarat). The unit is designed in such a way that it has unidirectional flow of material and personnel movement. Also, to avoid cross-contamination and to create a suitable environment for our penicillin products, we have set up a separate air handling system.

The store area that we have is spread over an area of 8410 sq. ft., whereas the production area is in the ratio of 40:60. All critical processing sections in our premises including tablet compression, dry mixing, sealing, capsule filling, blister packing, polishing, strip packing, etc., where the products are exposed to the atmosphere are designed for class 100000 condition. We have 3 and 5 micron air filtration in ancillary, which strengthens our infrastructural facilities. Furthermore, we keep our production area under negative pressure as compared to the adjacent cells. The critical products that we are always kept in the atmospheric temperature of 24+2C and Relative Humidity of less than 45%.

Our Projects

Till now we have accomplished many projects in our modern infrastructure that is spread on an area of 250000 sq. ft. Our premises has RCC Construction of 6000 sq. ft., Laboratory of 6000 sq. ft., Betalactum Unit of 40000 sq. ft., Utility Block of 6000 sq. ft., 64000 sq. ft. Main Block surrounded by landscape gardens & tar road covering 180000 sq. ft. It is the assistance of the mentioned facilities because of which we are capable of making 100% effectual Cloxispa Capsules, Spamclox Syrup, Cefalexin Oral Syrup, Co-Fluampicil Oral Syrup and all other products.

Quality Policy

We own a full-fledged quality control lab wherein raw and packing material are checked, end products are analyzed, stabilized study of finished items is carried out, microbiological testing is conducted and cleaning & calibration of instruments are done. A certified team handles this department and helps the company in maintaining optimum quality.

The following are the main sections of our quality control unit:

Sparsh Bio-Tech Pvt. Ltd. is registered under Company Act 2000, and works with the mission to offer the best products. We are counted among the top manufacturers, exporters and suppliers of Cloxispa Capsules, Co-Fluampicil Oral Syrup, Spamclox Syrup, Cefalexin Oral Syrup, etc. We not only conduct research work before carrying out the production process of our products but check the end products as well before their dispatch. Our company is proud to be a part of an industry that is serving mankind and promoting good health. We will keep on launching new products that will be more effective and can cure aliments just in few doses.

The support of our directors has enabled the company to grow and earn a reputed image in the market. The following are some names under whose guidance we have secured tremendous success in the industry:

Mr. P. N. Maru (Managing Director): He is a visionary person with an impressive sense of business and rich experience of over three decades.

Dr. A. J. Maru (Director): He holds a vast experience of around 26 years as a General Practitioner for Human Medicine. He is a successful businessman of Pharmaceutical Exports for 8 years and has a great way of handling operations.

Mr. R. H. Haria : He is an NRI director and was based in East African Countries for more than 20 years. He is the main handler for our Marketing and Sales operations in African Sector.

Mr. P. J. Maru & Mr. S. P. Maru: Both of them have rich experience in finance, sales and administration. They are the strongest assets to our company.

Our Presence

We are serving worldwide customers from various countries including India, Vietnam, Sri Lanka, Uganda, Congo, Kenya, Cambodia, Zambia, Rwanda, etc.

Quality Policy and Management System

We are committed to delivering the best quality of products like Cefalexin Oral Syrup, Spamclox Syrup, Co-Fluampicil Oral Syrup, Cloxispa Capsules, etc., that are effective. Our professionals follow all the quality norms while carrying out the different stages of the production process. The employees are trained in a particular function, which complies with cGMP before letting them handle floor operations.

We have hired quality inspectors who carry out inspection and make sure that all S.O.P. and B.M.R guidelines are being followed. These professionals also check the quality of the raw material, and without their approval no input is used by the production professionals. Also, the end product is not allowed to be delivered without the assurance of quality from our quality management team.

Our Plant

Our production plant is integrated with B-Lactum facilities, which help us produce Penicillin Anti-Biotic. The B-lactum facility that we own is certified by WHO-GMP (Food & Drug Control Administration of Gujarat). The unit is designed in such a way that it has unidirectional flow of material and personnel movement. Also, to avoid cross-contamination and to create a suitable environment for our penicillin products, we have set up a separate air handling system.

The store area that we have is spread over an area of 8410 sq. ft., whereas the production area is in the ratio of 40:60. All critical processing sections in our premises including tablet compression, dry mixing, sealing, capsule filling, blister packing, polishing, strip packing, etc., where the products are exposed to the atmosphere are designed for class 100000 condition. We have 3 and 5 micron air filtration in ancillary, which strengthens our infrastructural facilities. Furthermore, we keep our production area under negative pressure as compared to the adjacent cells. The critical products that we are always kept in the atmospheric temperature of 24+2C and Relative Humidity of less than 45%.

Our Projects

Till now we have accomplished many projects in our modern infrastructure that is spread on an area of 250000 sq. ft. Our premises has RCC Construction of 6000 sq. ft., Laboratory of 6000 sq. ft., Betalactum Unit of 40000 sq. ft., Utility Block of 6000 sq. ft., 64000 sq. ft. Main Block surrounded by landscape gardens & tar road covering 180000 sq. ft. It is the assistance of the mentioned facilities because of which we are capable of making 100% effectual Cloxispa Capsules, Spamclox Syrup, Cefalexin Oral Syrup, Co-Fluampicil Oral Syrup and all other products.

Quality Policy

We own a full-fledged quality control lab wherein raw and packing material are checked, end products are analyzed, stabilized study of finished items is carried out, microbiological testing is conducted and cleaning & calibration of instruments are done. A certified team handles this department and helps the company in maintaining optimum quality.

The following are the main sections of our quality control unit:

- Chemical Testing Section

- Instrument Room that is integrated with spectrophotometer, H.P.L.C, Karl fisher apparatus, disintegration, etc.

- Microbiological Section, where we have laminar airflow benches, colony counter, autoclave, incubator, etc.

- Documentation and Records Room

- Library

- Retention Sample Room

- Stability Testing Room

- G.M.P Training Room

- Testing room for packaging material

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free